The DCT dual-clutch transmission has long been Honda's technological flagship and has been an alternative to the traditional manual transmission in motorcycles since 2010. Recently, the Honda E-Clutch was added as an option, where the control of a conventional clutch is taken over by electronics. Completing the trio of alternative shifting technologies is the well-known quickshifter, which has become widespread since the introduction of electronic throttles. The operation of these various systems ranges from often explained to self-evident, but what does it look like from a purely technical perspective? Where is the wear greatest? Which system is the heaviest? Where are the greatest technical risks? Our tuning expert and motorcycle developer Martin Bauer has analyzed the shifting technologies and clarifies the advantages and disadvantages.

DCT, E-Clutch, Quickshift, or Manual Transmission? Pros and Cons

Engineer & Motorcycle Developer Explains Motorcycle Technology

Alternatives to the conventional manual transmission are becoming increasingly available in the motorcycle market. Honda alone offers four different shifting technologies. Engineer and motorcycle developer Martin Bauer explains the functionalities, advantages, and disadvantages.

&width=72&height=72&bgcolor=rgba_39_42_44_0&mode=crop)

Gregor

published on 12/9/2024

The sequential gearbox in motorcycles explained

Before we talk about the new special forms of shifting technology in motorcycles, Martin Bauer explains the standard transmission. Why is this necessary at all? To get moving, the power generated by the engine must be transferred from the crankshaft to the rear wheel. Depending on how you choose the gearing between the crankshaft and the rear wheel, a certain top speed is possible. Without a gearbox, only either strong acceleration with hardly any top speed, or top speed with hardly any acceleration is possible. It's like driving only in 1st or 6th gear. That's why a gearbox is needed, and in motorcycles, the sequentially shifted dog gearbox has become established.

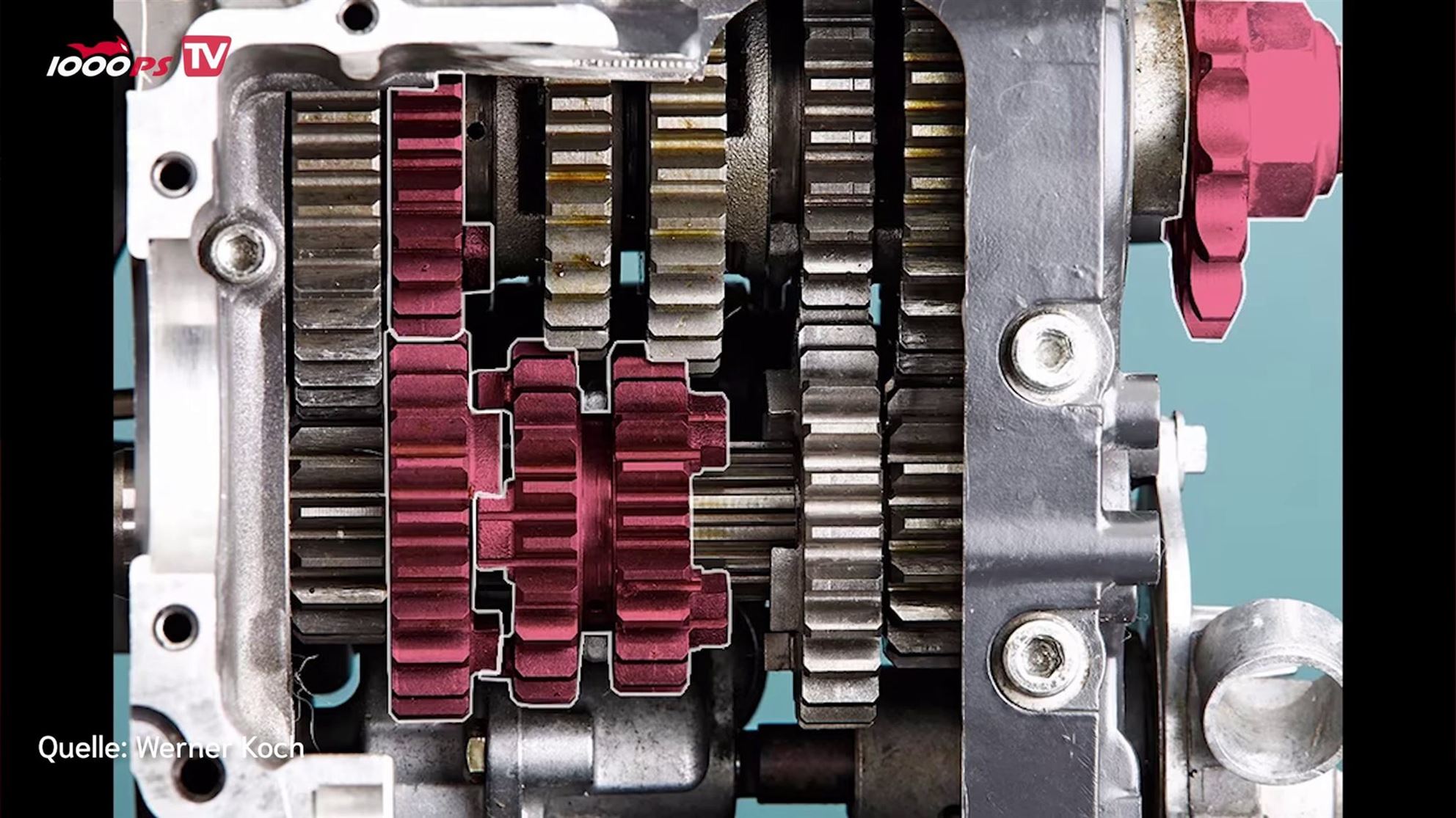

Here you can clearly see the gear pairs of the gears, which slide laterally over the shafts and interlock with the square claws.

On two shafts, the input and output shafts, usually sit six gear pairs, each representing a gear. The input shaft is connected to the clutch, which introduces the power from the engine, and on the output shaft sits the front sprocket, which is visible from the outside on most bikes and sets the chain in motion. During the shifting process, the vertical movement of the shift lever is first converted into a lateral movement along the shafts. There are various technical solutions for this conversion; roughly speaking, a shift drum with milled grooves is rotated, which then moves so-called shift forks along the shafts via these grooves. When the gears on the shaft are shifted, they disengage and interlock with each other. This is where the eponymous claws come into play. The metallic lateral extensions of the gears hook into the next gear. However, for these claws to have time to disengage or interlock, the transmission must be shifted without load. Under power and at high rotational speeds of the gears, the claws would only strike instead of engaging. To achieve a load-free transmission, the clutch is usually pulled, thereby disconnecting the power supply from the transmission, allowing the old gear to disengage and the next one to engage.

Quickshifter explained in motorcycles

This described shifting process with disengaging the clutch, engaging the gear, and re-engaging the clutch takes quite a long time, which is why especially in racing, quick alternatives were sought. Actually, the clutch is not strictly necessary, because with a bit of practice, a quick throttle on-off with a precise shift impulse is enough to let the gear engage in the momentarily unloaded transmission. Many experienced motorcycle riders shift through the gears this way. The first quickshift systems electronically simulated this process by simply interrupting the ignition, or injection, or both at the moment of shifting. The electronics are faster and more precise than a human, but for the transmission, there is essentially no difference between these two methods. However, this simple quickshifter technology had the disadvantage that it did not work when downshifting. Because the transmission is not load-free with the throttle closed, as the engine brake acts during deceleration.

Quickshifters are now almost standard on modern bikes. When properly configured, they offer only advantages.

To achieve this next step, electronic throttle control, known as ride-by-wire, was needed. This allows the control electronics to do the opposite of a quickshifter when upshifting. Instead of cutting the throttle, a precise throttle blip is given, bringing the revs exactly to the level needed to synchronize the two shafts in the gearbox. Now, the gear dogs can disengage and re-engage without load. Throughout the entire process, the clutch is not used.

Quickshifter on Motorcycles - Pros and Cons

The advantages of quickshifters are quite obvious, and many sporty motorcycle riders no longer want to do without shift assistants on their bikes. At the same time, there's often a rumor that quickshifters put more strain on the gearbox components. Martin Bauer explains why this is only partially true. If the timing of the load interruption periods is incorrect, the gearbox can indeed be affected. For example, if power is sent back to the transmission while the next gear hasn't fully engaged with the dogs, they can hit the edges and become rounded. This can lead to gears not engaging or popping out. Such a case can occur with aftermarket quickshifters if poorly tuned, but Martin Bauer sees no increased risk of such defects with established manufacturers who have the necessary know-how and testing procedures in development. If the gearbox is correctly shifted without load, the components are not subjected to more stress than during a gear change with the clutch.

Honda E-Clutch Pros and Cons

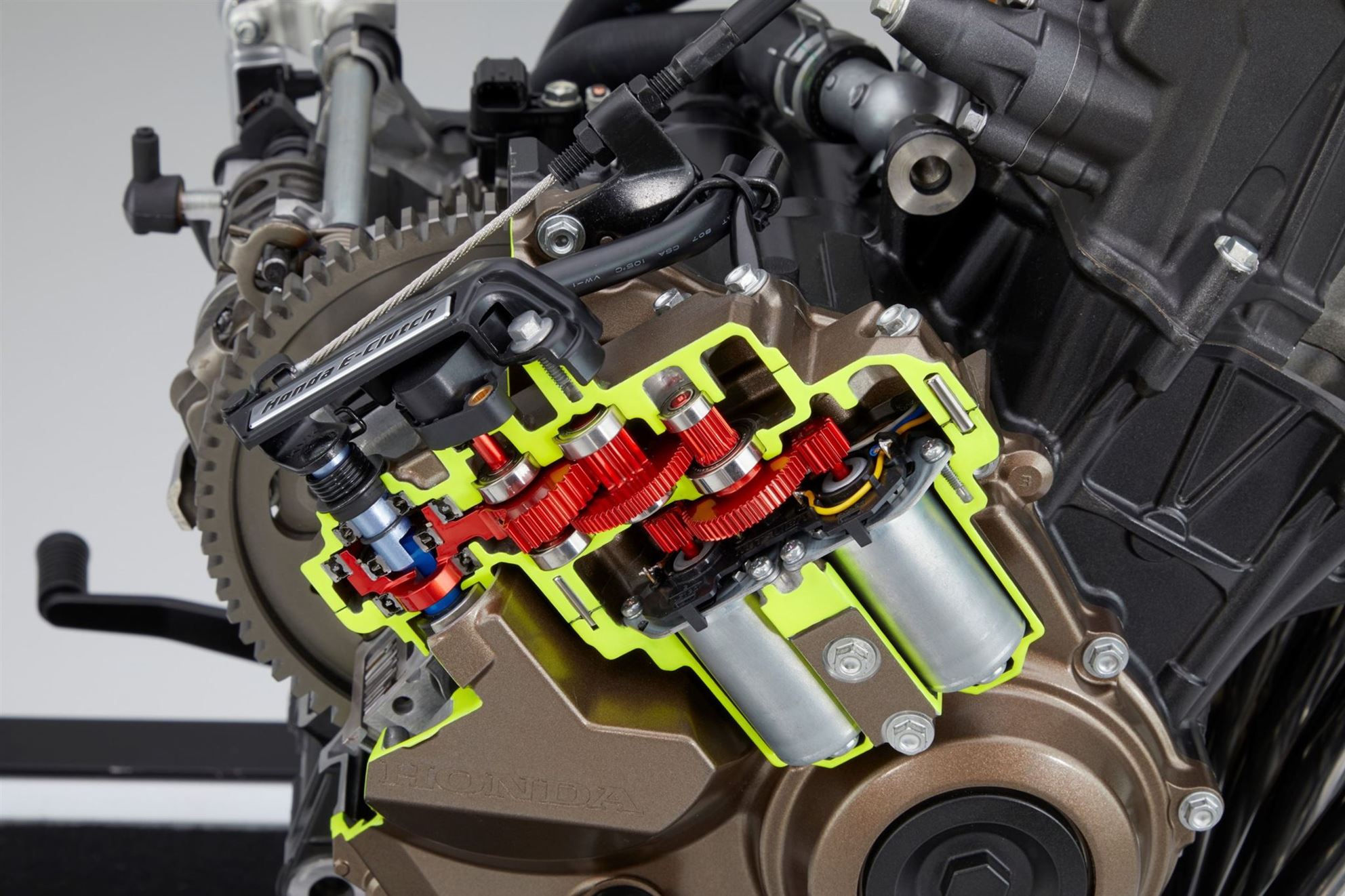

It's all the more interesting that Honda is now bringing the clutch back into play with the new E-Clutch shifting technology. The E-Clutch features a conventional clutch and gearbox, but the control of the clutch can be done both manually via cable and electronically. This works by having the small shaft on the outside of the clutch cover, where the clutch cable attaches, split into two parts. The upper half is operated manually via the cable, while the lower half is controlled by electric motors. This allows the advanced control electronics to modulate the otherwise conventional clutch, so the rider doesn't have to reach for the lever when stopping and starting. However, since the upper half of the shaft engages with the lower part when the clutch is disengaged, manual intervention is possible at any time, effectively "overriding" the electronic control. The gearbox, on the other hand, is completely normal, and the rider shifts through the gears in the traditional manner. The electronic clutch assists with shifting, making it smoother and allowing for downshifting under full throttle or upshifting during deceleration. We took a closer look at how well this works in practice during the test of the Honda CB650R E-Clutch.

Honda's E-Clutch technology is, unlike the DCT, very easily compatible with the conventional clutch and gearbox of existing motorcycle models. It is expected that more Honda models will soon offer the E-Clutch as an option.

The advantages of the E-Clutch system are clear. In stop-and-go traffic, the automation of the clutch provides more comfort, and gear shifts with the quickshifter are smoother and possible at any time. A commonly cited disadvantage is the potential increase in sources of error. However, Martin Bauer doesn't see much risk here. Sure, the sensors and electric motors of the E-Clutch can fail, but by now, such components are also installed in almost all modern new motorcycles with conventional shifting technology. Accordingly, the technology is well-developed. Moreover, the clutch should not be excessively stressed by the E-Clutch. Honda states that during extensive tests conducted during the development of the E-Clutch, the wear of the clutch plates was at the same level as with manual clutch operation by experienced motorcycle riders.

Honda DCT Dual-Clutch Transmission Explained

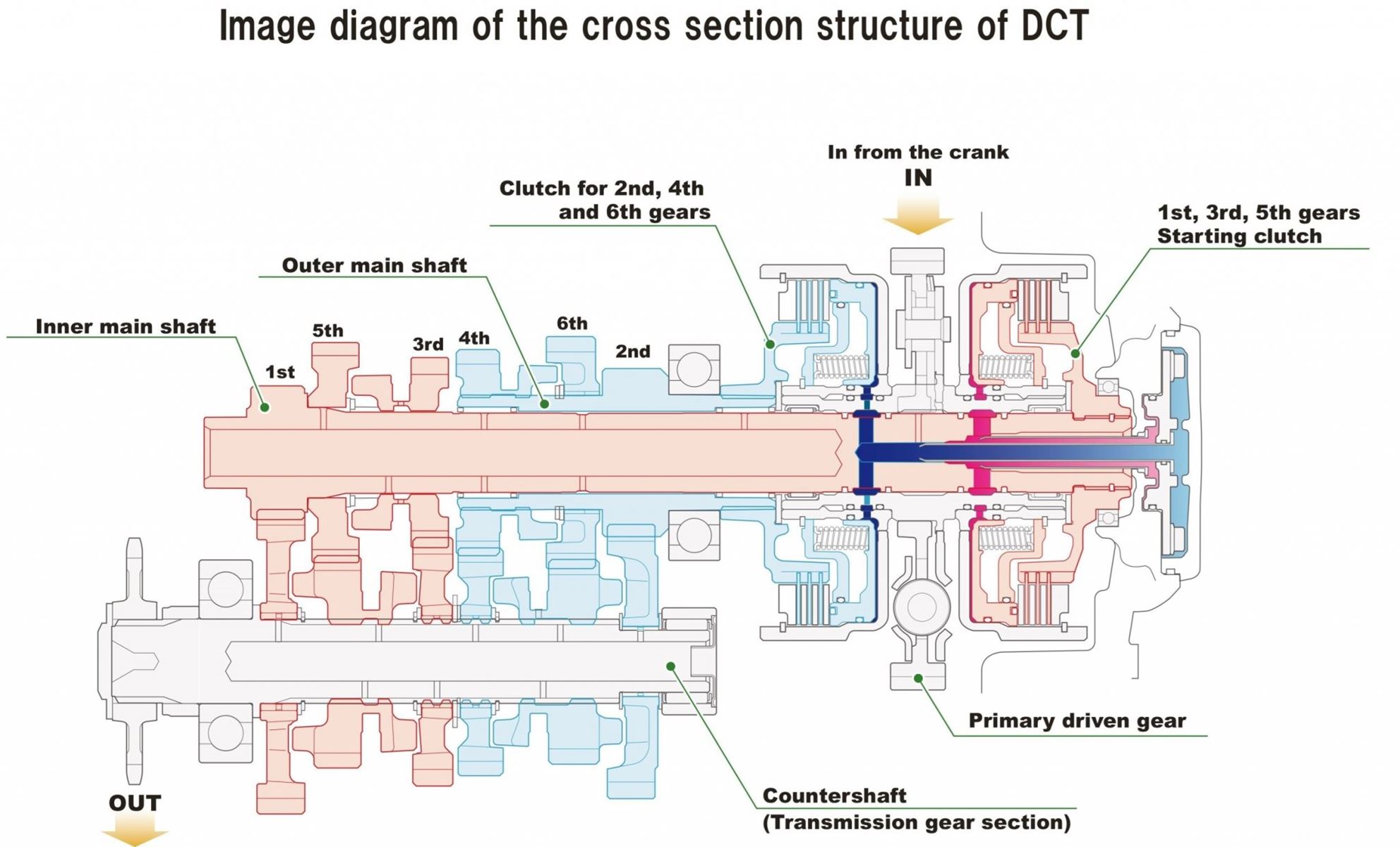

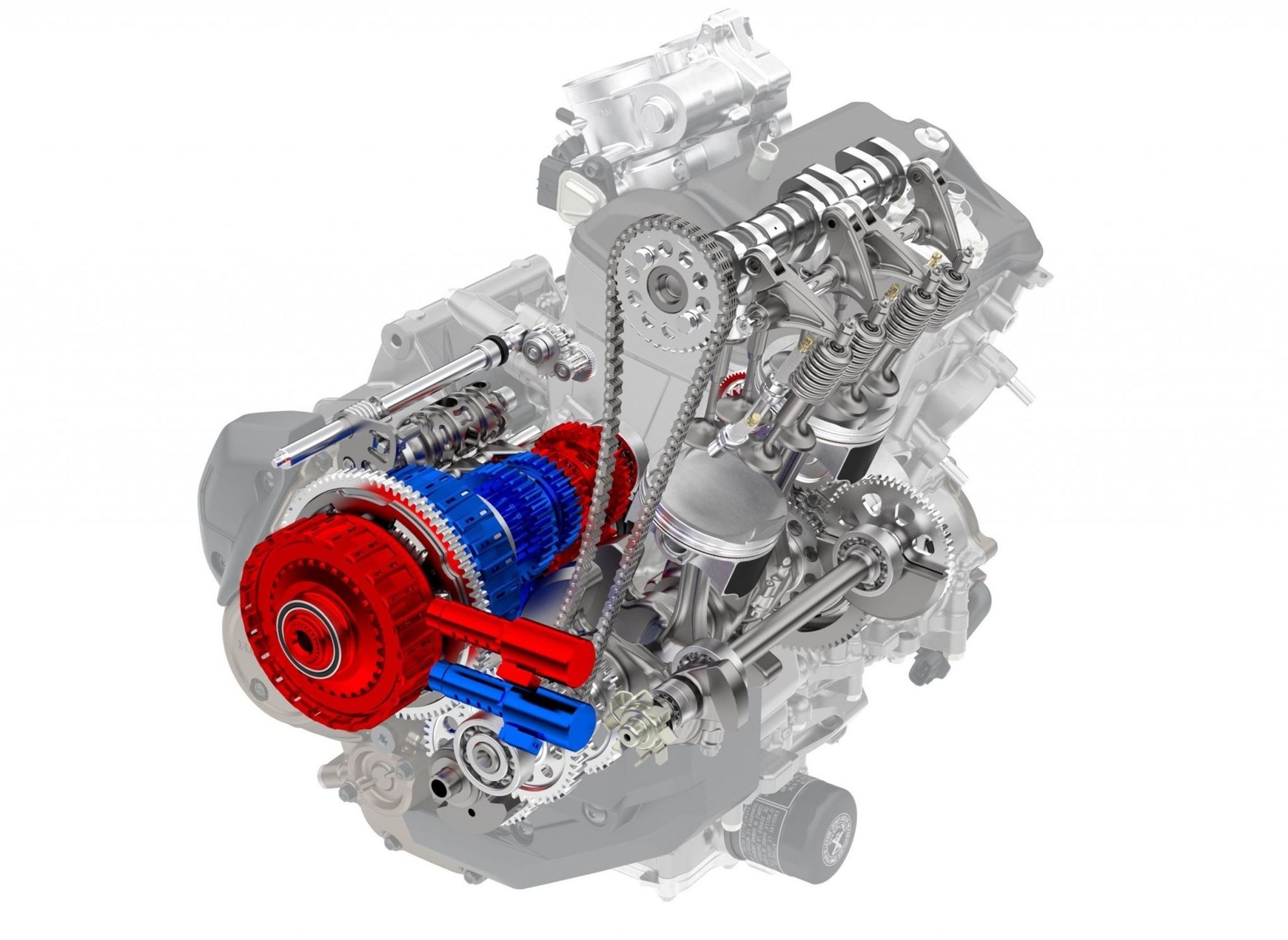

In conventional gear shifts, whether with or without a quickshifter, there is inevitably a pause in acceleration or deceleration, leading to at least slight load changes. Therefore, Honda began considering in the early 2000s how to minimize this interruption and the jolt during shifting. The idea: For the gear change to be as fast and smooth as possible, the next gear must already be engaged before the gears of the previous gear disengage. This led to the development of the now-legendary DCT dual-clutch transmission, which is offered in numerous Honda models. The input shaft of the transmission is divided into two shafts, each equipped with a clutch and three gears (1st, 3rd & 5th gear on one and 2nd, 4th & 6th gear on the other shaft). The clutches operate independently of each other. For example, if the first gear is engaged, the clutch for the second gear is already preloaded. To switch gears, clutch 1 simply needs to disengage from the first gear while clutch 2 engages with the second gear. This can happen synchronously, resulting in minimal time interruption and load change. This is coupled with an electronic control of the manual transmission, allowing the motorcycle to shift automatically, taking into account additional data from the extensive sensor system and at predefined engine speeds.

Two input shafts and two clutches allow for lightning-fast gear changes with the DCT, almost without noticeable interruption in power delivery.

Honda DCT Dual-Clutch Transmission Pros and Cons

Many advantages of this technology are obvious. The time without load on the rear wheel is minimized, and gear changes are much smoother and jerk-free. During spirited riding, acceleration is faster and more harmonious, while during relaxed touring, comfort increases due to automatic and almost imperceptible gear shifts. Stalling the engine is also no longer possible, which is a significant advantage for beginners or in off-road use, as I discovered during the DCT test in Iceland. Finally, the DCT technology also enables physically challenged individuals, who can no longer operate a conventional gearbox, to enjoy motorcycling.

All the possibilities and features of the DCT come at a price: The DCT requires a lot of space and adds extra kilograms. This is not compatible with every type of bike.

But are there any downsides? Due to the many additional components, the DCT system adds 10 kilograms of extra weight. This, along with the increased space requirement, is the main reason why the DCT has yet to find its way onto a sports bike, where every kilogram counts. However, in touring motorcycles, the weight increase is less critical. Here, too, the question of susceptibility to faults arises in light of the complex technology. Even with the DCT, there seems to be no increased risk of failure. In addition to high DCT sales figures and the absence of negative headlines, our in-house long-distance rider Varahannes probably offers the best proof of the DCT's reliability. He has clocked up 520,000 km on his 2016 Africa Twin. In all those years and kilometers, he only had one defect with the transmission's shift motor, nothing else. Even after more than half a million kilometers, the original clutch plates are still in his Africa Twin, despite primarily using the DCT for deceleration to preserve the brake pads. So, it can be said with confidence that the DCT is very robust.

Cost Comparison of Shift Technology - Quickshifter vs. E-Clutch vs. DCT

Quickshifters come in such a variety and different versions that a flat price cannot be determined. Some manufacturers charge €200, while others offer the shift assistant only in larger accessory packages, which often exceed €1,000. For the sake of comparison, let's take the optional quickshifter of the Honda CB650R as an example, for which you have to pay €222 in Austria. The E-Clutch system costs an additional €500 for the same motorcycle. The DCT is the largest system with the most features and therefore costs more. Depending on the motorcycle model, an additional €1,000 to €1,200 is required.

DCT, E-Clutch, Quickshift, or Manual Transmission? Pros and Cons Images

Source: 1000PS

Honda E-Clutch

Honda DCT Doppelkupplungsgetriebe

Motorrad Schaltgetriebe

Honda E-Clutch

Honda E-Clutch

Honda DCT Doppelkupplungsgetriebe

Honda E-Clutch

Honda E-Clutch

Honda DCT Doppelkupplungsgetriebe

Motorrad Schaltgetriebe

Honda E-Clutch

Honda E-Clutch

Honda E-Clutch

Honda E-Clutch

Motorrad Schaltgetriebe

Motorrad Schaltgetriebe

Honda DCT Doppelkupplungsgetriebe

Honda E-Clutch

Motorrad Schaltgetriebe

Motorrad Schaltgetriebe